Counterfeit-proof product packaging

Protection against plagiarism and counterfeiting can be done in two ways:

Either via a forgery-proofing of the product itself or through a logistical chain that has been completely recorded and secured. In the ideal case, but also by a combination of both.

Through the use of today's technologies and processes, we are now in the position for the first time to map a transport and logistics chain in this form. The use of such logistics no longer makes counterfeit security at the product level absolutely necessary.

This not only reduces the direct financial damage caused by product piracy, but also the indirect, if, for example, the manufacturer unjustified warranty claims are made, caused by inferior counterfeits.

In Germany alone, the estimated direct financial loss is more than € 30 billion in 2016. In Europe, around 200,000 jobs resulting from product piracy were destroyed during the same period (source: DIHK and ICC).

Many companies do not invest because they expect short-term imitations of their new products. The result is a loss of brand value and damage to the image, which attach more importance to the company than the financial loss due to the loss of sales.

If safety standards are neglected, health or even life are endangered!

Some examples are drugs with wrong or no active ingredients, counterfeit pesticides in agriculture, defective spare parts or toxic colors in toys and textiles.

Determining the production sites of counterfeiters is an unsolvable task - BUT: All products have to be transported and the information about the transport routes can be inferred, whether it is a forgery.

Our system provides a fully controlled total logistics chain, starting with the supply industry, through production, wholesale / retail to consumer.

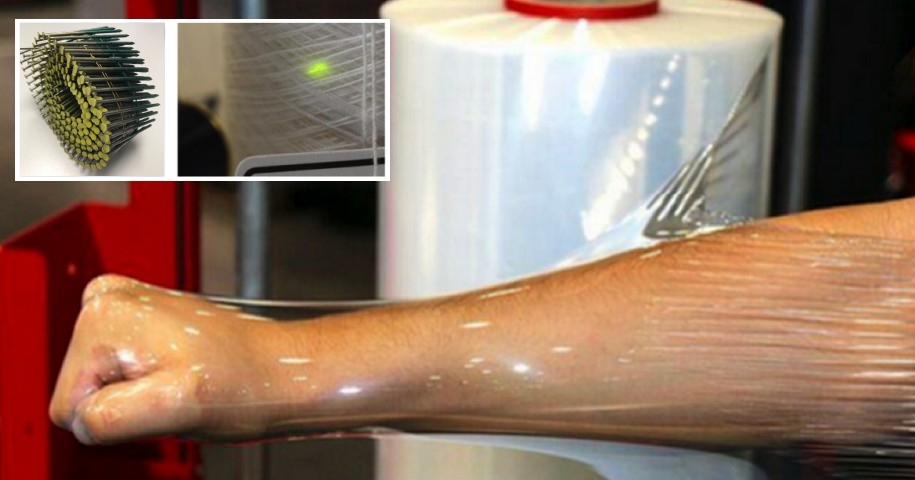

In addition to the load carriers and the products, the outer packaging (stretch films, seal stickers, adhesive tape, etc.) can also be equipped with a chemical marker which is considered to be forgery-proof and which can be incorporated into thousands of different color shades during the injection molding process in the load carriers and / or packaging materials , Since a small amount of the marker is sufficient here, this method is also very cost-effective. The dosage of the marker additive is in the ppm range. Our RFID Reader + Marker Detector solution recognizes the corresponding marker as the original and the organizational unit assigned to the marker.